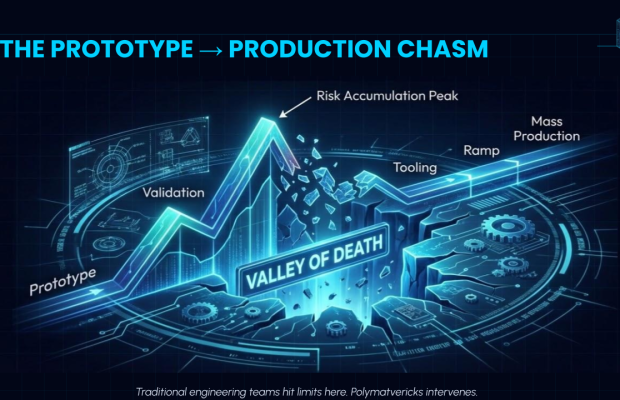

Don't Let the "Valley of Death" Kill Your Product

We help robotics and advanced electronics companies scale from prototype to production without structural failure.

The Industry Problem

Most robotics and advanced electronics companies fail not because the tech doesn’t work, but because they cannot scale from a lab prototype to a mass-manufacturable product.

Production exposes weaknesses that prototypes conceal:

- Architecture fragility under production load

- Sim2Real gaps between simulation and field performance

- Compliance and validation blind spots

- Manufacturing and supply chain instability

- Operating model misalignment across teams

The Polymatvericks 5-Pillar Operating Model

We quantify structural readiness across Architecture, Sim2Real, V&V & Compliance, Manufacturing & Supply Chain, and Operating Model.

Architecture

System integrity under scale.

Sim2Real

Model-to-reality alignment.

V&V & Compliance

Validation governance.

Manufacturing & Supply Chain

Production stability.

Operating Model

Execution governance.

Bridging Agile Velocity and Safety-Critical Rigor

Polymatvericks’ operating model discipline was shaped at the intersection of software-velocity environments, safety-critical aerospace systems, and production-scale manufacturing.

We integrate gaming-grade iteration speed, aerospace systems rigor, and OEM and Contract manufacturing realities into a unified governance framework for hardware scale.

Meet the Bridge Builder

Chioma Aso’s career spans safety-critical engineering at Lockheed Martin, software velocity at Electronic Arts, and production-scale manufacturing at Jabil and Watchfire Signs.

The intersection of aerospace rigor, gaming-grade iteration, and both CM and OEM manufacturing reality, is the foundation the Polymatvericks framework was built on.

Engagement Methodology

Phase I

Tactical Audit

We define structural exposure, scale posture, and priority alignment before production load.

- 5-pillar structural assessment

- Executive Summary

- Technical Gap Analysis

- Board-ready findings

Standalone engagement with board-ready deliverables.

Required before implementation.

Phase II

90-Day Implementation

We work alongside engineering leadership to operationalize audit findings and calibrate the operating model for scale.

- Operating model instrumentation

- Cross-functional alignment

- Risk compression across pillars

- Production readiness acceleration

Collaborative implementation.

Minimum 90-day engagement.

Phase III

Strategic Oversight

Continued advisory support during production ramp, with targeted recalibration as complexity increases.

Optional ongoing engagement.

What you gain from working with us

Each engagement is designed to leave your organization structurally stronger and better informed.

Predictable Scale Reliability

Your hardware performs under production load because the structural weaknesses were identified and resolved before they became costly surprises.

Execution Clarity for Boards & Investors

Decision-makers receive documentation built for action, not slide decks that require interpretation. Capital deployment becomes deliberate, not reactive.

Cross-Functional Engineering Cohesion

Hardware and software teams move in the same direction. Handoff failures and decision bottlenecks get replaced with aligned execution cadence.

Supply Chain Resilience

Supplier dependencies and production vulnerabilities are mapped before ramp, so disruptions are anticipated and managed rather than absorbed at scale.

Governance for Human-Machine Workflows

The operational interfaces between people and systems get structure. Nothing is left to assumption. Workflows that appeared functional at prototype scale hold up under production pressure.

Risk-Based Execution Prioritization

Your team stops reacting and starts sequencing. Engineering effort is directed toward the highest-leverage risks, not the loudest ones.

An Organization Ready to Perform Under Load

The cumulative result of structural engagement is an organization that knows exactly where it stands before production. A company built to scale.

Scale Without Structural Failure

Scale exposes weakness.

Structure prevents it.

We build the systems that allow products to scale.